No app or updates to install

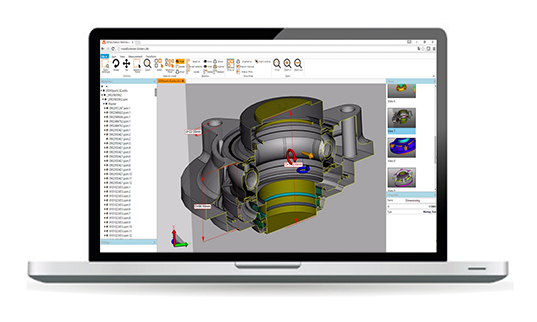

3DViewStation WebViewer is the browser-based counterpart to our desktop edition. It offers identical, rich functionality and performance.

Quickly view CAD data on notebooks, tablets or smartphones. This edition is compatible with mobile devices running Windows, Android, iOS or Linux operating systems.

Use as stand-alone software or integrate it into any leading product lifecycle management (PLM) system using APIs. It’s commonly paired with product configurators, after sales & service solutions and even on machines in the human-machine interface (HMI).

3DViewStation WebViewer does not transfer any 3D geometries to the end device, protecting sensitive CAD data.

Your benefits

Highlights

Reads over 60 data formats

Reads over 60 data formats

- 3D import – native & neutral CAD:

Catia, NX, Creo, Solidworks, SolidEdge, Inventor, SAT, Parasolid, JT, STEP, 3D PDF, Revit, GLTF, 3DXML, STL, VRML - 2D import – drawings, office, pictures:

Catia CatDrawing, NX 2D, Creo DRW, Solidworks slddrw, DWG, DXF, HPGL, 2D PDF, TIFF, JPEG - 3D export:

STEP, JT, 3D PDF, 3MF, Parasolid, STL,VRML - 2D export:

DXF, PDF, CGM, PNG, SVG, BMP

- 3D import – native & neutral CAD:

Offers more than 180 functions

Offers more than 180 functions

Standard viewing capabilities include measuring & dimensioning, cutting and comparing.

Achieve model based definition (MBD) as you replace 2D drawings with 3D models. When you use the 3D Master conceptual design, you also get product manufacturing information (PMI) support. Besides viewing existing PMIs, create your own markups and views, transform them into PMIs, and save them as JT or STEP AP242 files.Performs advanced digital mock up (DMU)

Performs advanced digital mock up (DMU)

We’re no longer building physical prototypes before manufacturing products. To develop products faster and reduce costs, the digital mock up (DMU) process maps as much information as possible in a digital product at the earliest stages and carries out virtual simulations. Very early on, collision checks identify potential problems in production, assembly or ongoing operations.

Since this process is both creative and iterative, DMU becomes more about the advanced functions, complex calculations and sophisticated graphical output or renderings. You’re not loading and measuring two JTs, but rather subjecting a Catia and possibly an NX module to a collision investigation in one scene.